Further work is currently underway to investigate whether a combined process of high temperature brazing and 3d printing can significantly improve the efficiency of additive manufacturing methods for ceramic materials.

Can i resistance braze ceramics.

The development of more advanced types was promoted by the challenge to confront service conditions at elevated temperatures in oxidizing or corrosive environments with substantial mechanical properties.

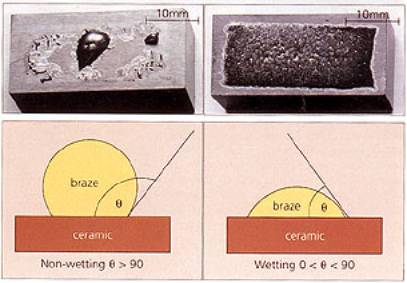

Metal to ceramic brazing can be accomplished by first applying a metallic layer onto the ceramic surface or by braz ing directly to the unmodified ceramic oxide surface.

The new phase formed may be much less corrosion resistant than the ceramic or the brazing filler metal or the differ.

Brazing is a liquid phase process that is a well established technique for the joining of ceramics.

Many times the brazing filler metals form intermediate phases with the ceramic or the matrix material in case of compos ites altering the chemical composition locally.

Active metal braze alloys eliminate process steps allowing you to braze directly to raw ceramics with prior heal firing without having to metalize plate the surface prior to brazing.

Filler metals often used to braze ceramics have infe rior corrosion resistance.

Alloys with such properties include pt cu ti pd ni ti and co ti.

This website requires certain cookies to work and uses other cookies to help you have the best experience.

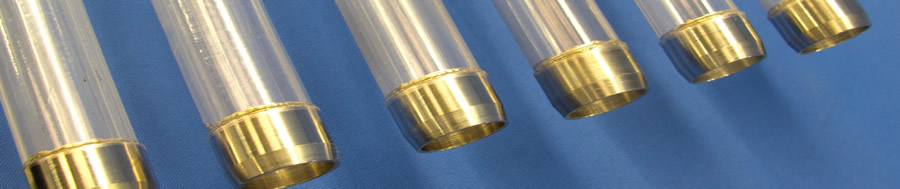

At altair technologies we routinely braze ceramics particularly alumina but can also braze zirconia quartz fused silica beo aln si sic and other ceramic like or composite materials.

Development of high temperature stable composite materials based on nita and tial braze compositions.

Can i braze metals to ceramic.

Ideally these alloys will retain their strength and ductility at temperature as well as having good oxidation resistance.

It has been shown that one active braze alloy 60ta 30w zr can be used to join graphite for use in excess of 2700 c.

Brazes melt at temperatures greater than 840 f 450 c and upon cooling the solidified joint stresses can fracture or distort a part.

Posted by wpengine on september 17 2020 8 45 pm leave a comment brazing is used to join metal parts and can be applied to a wide array of materials like brass copper stainless steel aluminum zinc coated steel and ceramics.

Brazing is a highly versatile joining technique that can even allow metals to be permanently bonded to certain structural ceramic materials.

W hen considering braze attachment of ceramics to metals the issue of cte is limiting.

The solder or braze attachment process can be further differentiated.

What metals can you braze.

Earlier ceramics were intended to withstand service at room temperature essentially displaying insulating properties and wear resistance in absence of shocks.