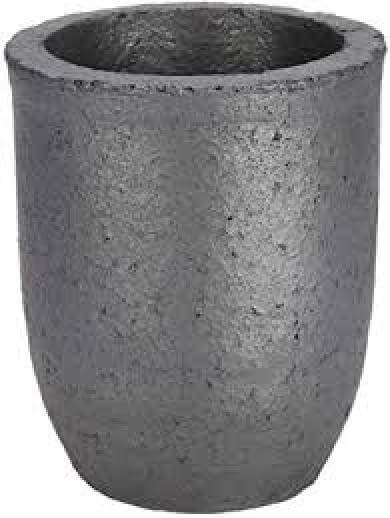

Carbon bonded and ceramic bonded clay graphite and silicon carbide crucibles are widely used in melting aluminium and aluminium alloys aluminium bronze copper copper based alloys cupro nickel and nickel bronze alloys precious metals zinc and zinc oxide.

Carbon bonded and ceramic bonded clay graphite and silicon carbide crucibles.

These crucibles are mostly used for melting non ferrous precious metals such as brass copper nickel chromium as well as their alloys.

Crucibles are manufactured in two basic compositions.

Motive power 80 kw.

Crucibles are also used in melting cast iron.

Carbon bonded and ceramic bonded clay graphite and silicon carbide crucibles are widely use in melting and holding aluminum and aluminum alloys aluminum bronze copper and copper based alloys cupro nickel and nickel bronze alloys precious metals zinc and zinc oxide.

When compared to clay bonded graphite crucibles.

Is 11321 1985 graphite for graphite crucible is 12817 1989 carbon bonded silicon carbide crucibles.

Isostatically pressed carbon bonded crucibles with very low electric resistivity.

Market potential in view of the fast development in the industrial activity in the fields of foundry carbon bonded silicon carbide crucibles.

Foseco offers the foundryman a complete range of silicon carbide and clay graphite crucibles retorts and other specialised shapes for use in fuel fired.

The clay graphite ceramic bonded and the silicon carbide carbon bonded.

Carbon bonded silicon carbide crucibles.

Foseco offers the foundryman a complete range of silicon carbide and clay graphite crucibles retorts and other specialized shapes for use in fuel fired.

We doesn t provide carbon bonded silicon carbide crucibles products or service please contact them directly and verify their companies info carefully.

Crucibles and crucible base blocks.

Crucibles refractories and ceramics.

Both types utilize the refractory materials graphite and silicon as conductors of heat and for structural.

Performance specification isostatic pressed crucibles will reduce energy cost and extend crucible life.

The profile envisages setting up a unit for manufacture of 300 tonnes of carbon bonded silicon carbide crucibles valued at rs 1 65 crores per annum.

Crucibles refractories and ceramics.

Glazes are available for most non ferrous applications and in high and low temperature varieties.

Isostatically pressed carbon bonded crucibles with very low electric resistivity.

Less dense and more porous crucibles may allow erosion.